2S Naval Gas Turbine

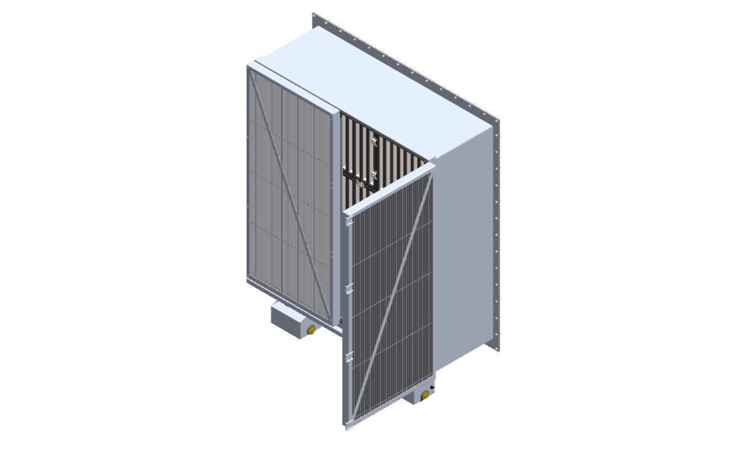

Standard module accommodating 32kg/s at 15degC [2m x 2m x 0.75m].

We implement our innovative 2S Design Architecture as follows:

- 2S/M6

- 2S/M6+

- A custom 2S/F7 is also available

All solutions meet with the following typical specifications:

- Salt ingress <0.0015ppm, average and <0.01 ppm max

- Water ingress <0.5% of air flow

- Dust ingress <0.004grains/1000 ft3

- Salt content downstream < 0.01ppm by weight

Our systems feature 2 market firsts:

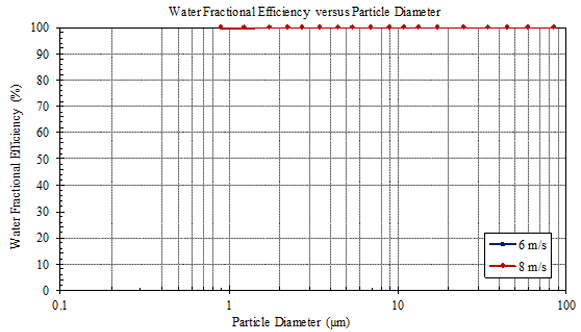

- Highest water removal (and salt in wet state) reliability, as measured by the ISO:29461-2

- Highest water removal (and salt in wet state) efficiency, up to 100% at 0.8micron droplets

PRODUCTS AND SOLUTIONS

Contact For Services

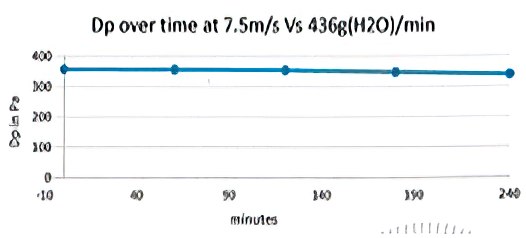

ISO:29461-2 water test

- No water penetration throughout the test.

- Downstream duct dry to touch after removing filter.

- Downstream media dry to touch at end of test.

Water Removal Efficiency

Pro Web Dubai.

Pro Web Dubai.