2S Diesel Generators & Propulsion

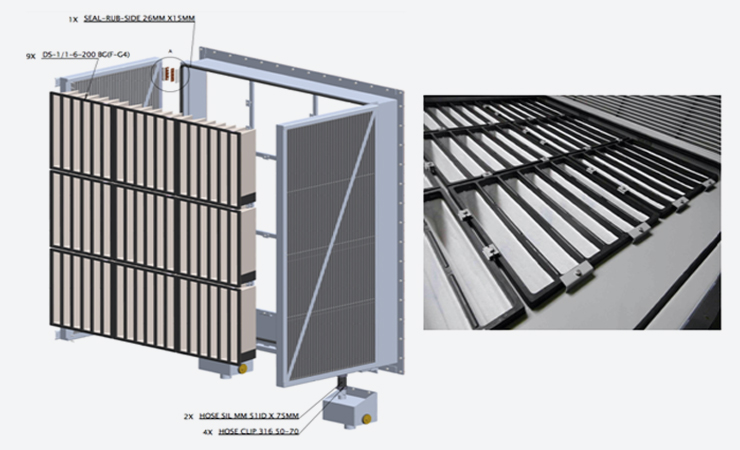

Standard module accommodating 25kg/s at 15degC [2m x 2m x 0.35m].

We implement our innovative 2S Design Architecture as follows:

- 2S/G4 with depths from 340mm to 750mm

- 2S/M5 with depths from 340mm to 750mm

- 2S/M6 with depths from 340mm to 750mm

All solutions meet with the following typical specifications:

- Salt ingress < 3% at 100% RH

- Dust content < 0.05mg/m3

- Salt content < 0.01ppm

- Salt content < 1mg/m3

Pro Web Dubai.

Pro Web Dubai.